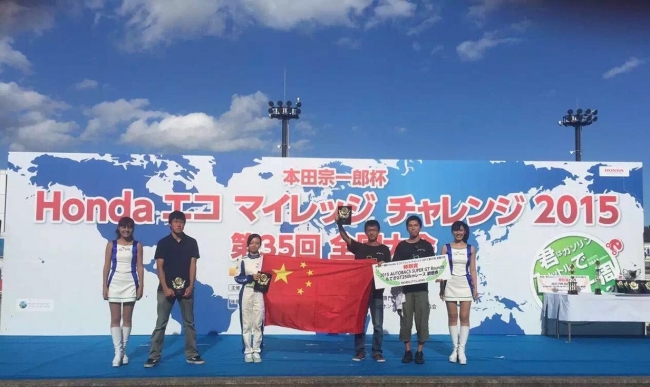

Tongji Zeal Eco-Power motorcade won first place In the 35th HondaSoichiroCup (Japan) Energy Conservation Competition, which ended on September 20, 2015. Tongji completed in the new-challenging group with an excellent speed of 1905.236km/l, which was its best score since it began to participate in the competition in 2000. This is not only the motorcade’s third championship in foreign competitions (the first one wasthe best team of the diesel vehicle group inShell Eco-marathon Asia Competitionheld in Malaysia in2012. The second one was the best team of the diesel vehicle group in Shell Eco-marathon Asia Competition held in Philippines in 2014. However, it is the first championship won by the Chinese motorcade in the Soichrio Cup competition.

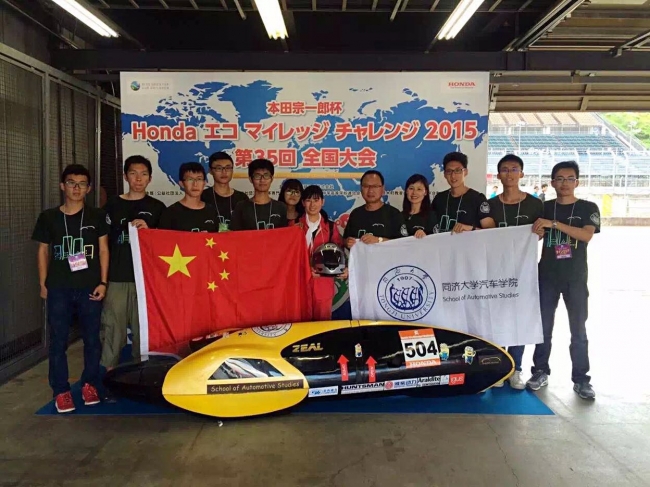

Tongji Zeal Eco-Power, founded in 2000, is affiliated with Automotive College’s Innovation Base with a history of 15 years. The motorcade aims to promote the development of environmental protection technology and to make full use of the earth’s limited resources. It designs an energy-conserving race car for the purpose of challenging the limit of automotive fuel consumption. The motorcade participates in the Honda Soichiro Cup (Japan) Energy Conservation Competition, Honda Soichiro Cup (China) Energy Conservation Competition and Shell Eco-marathon Asia Competition every year. These competitions serve as a test platform and the motorcade has made several breakthroughs in overcoming the technical barriers and minimizing the automotive fuel consumption. Competitions in Japan do witness the growth of Tongji Zeal Eco-Power: from failing to finish the race in the first to completing the full distance, from having scores far behind Japanese motorcades’ to step by step making breakthroughs to win the championship at last.

After 15 years of hard work from generations of the motorcade members’ efforts and experience that helped Tongji Zeal Eco-Power win the championship. Over the years, each team has inherited previous motorcades’ technology and has continued to make significant improvements, including: light weight, engine performance optimization, low wind resistance and low friction. This year, the motorcade further improved the engine performance, especially in the engine’s electrical controls; equipping it with sensor information acquisition and feedback and display functions. Meanwhile, it optimized battery and rear cabin air influx, thus improving the total performance and ensuring the automobile’s excellent functionality and reliability.